You are looking for a pump for dewatering feed applications and moving higher percent solid sludge through a wastewater plant. You are presented with three different types of pumps, including a rotary lobe, a progressive cavity and a double disc pump. Each can handle the task at hand. Each operates relatively smoothly and quietly. So, which do you choose?

At first glance when you are reading the pump specs, each of the three pump types seem like they are interchangeable. However, one of the pumps features a critical difference in technology design that significantly impacts operations.

Two begin to experience wear from the very first day of operation, while the third one does not. In addition, two seem to have a lower initial cost, but the third offers a lower total cost of ownership over the lifetime of the pump, making it more cost effective over the long haul.

Progressive Cavity and Rotary Lobe Pumps

Progressive cavity and rotary lobe pumps share a variety of the same characteristics:

- A close tolerance design that incorporates a rubbing action or very tight tolerance to generate flow

- Inability to run dry for any period of time without becoming damaged

- Unable to pass larger solids

- Abrasive materials, like grit and sand, can drastically increase the pump’s wear rate

By design, both the progressive cavity and rotary lobe pumps experience friction wear on relatively clean sludges. Efficiency is lost during operation because tolerances open up and result in a drop in flow. Because of this, the pump needs to increase speed to achieve the desired flow rate. This drastically increases the wear rates. These pumps cannot run dry without seizing up.

The typical operating life for rotary pump designs can range from 3,000 to 5,000 hours before a rebuild is required and are expensive to rebuild. Spare parts can cost anywhere between 50% to 100% of the initial capital purchase price of the pump. The initial investment in a rotary pump can be low, but the total cost of ownership over the pump’s lifetime increases drastically as maintenance and rebuilds are required.

Double Disc Pumps

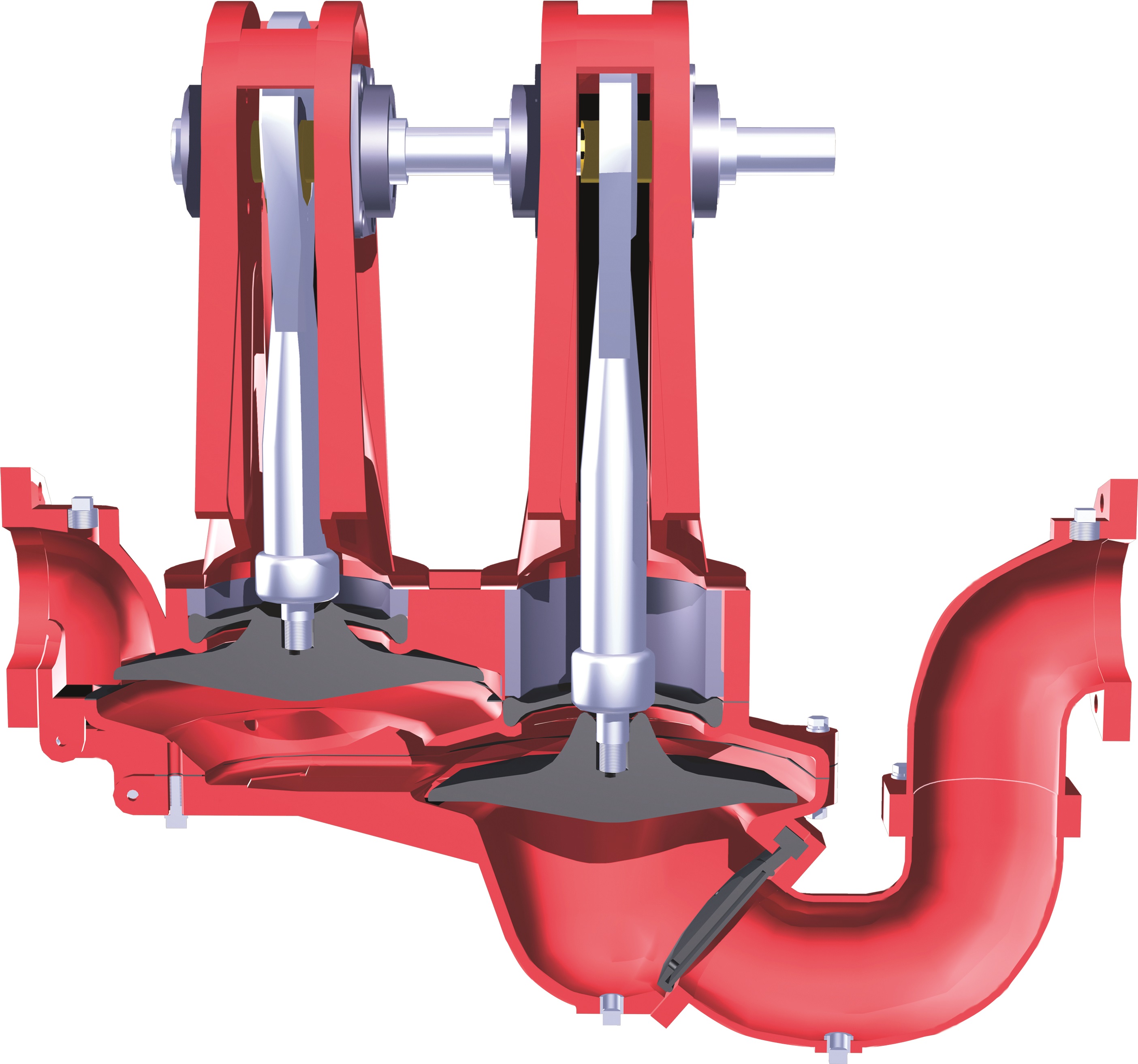

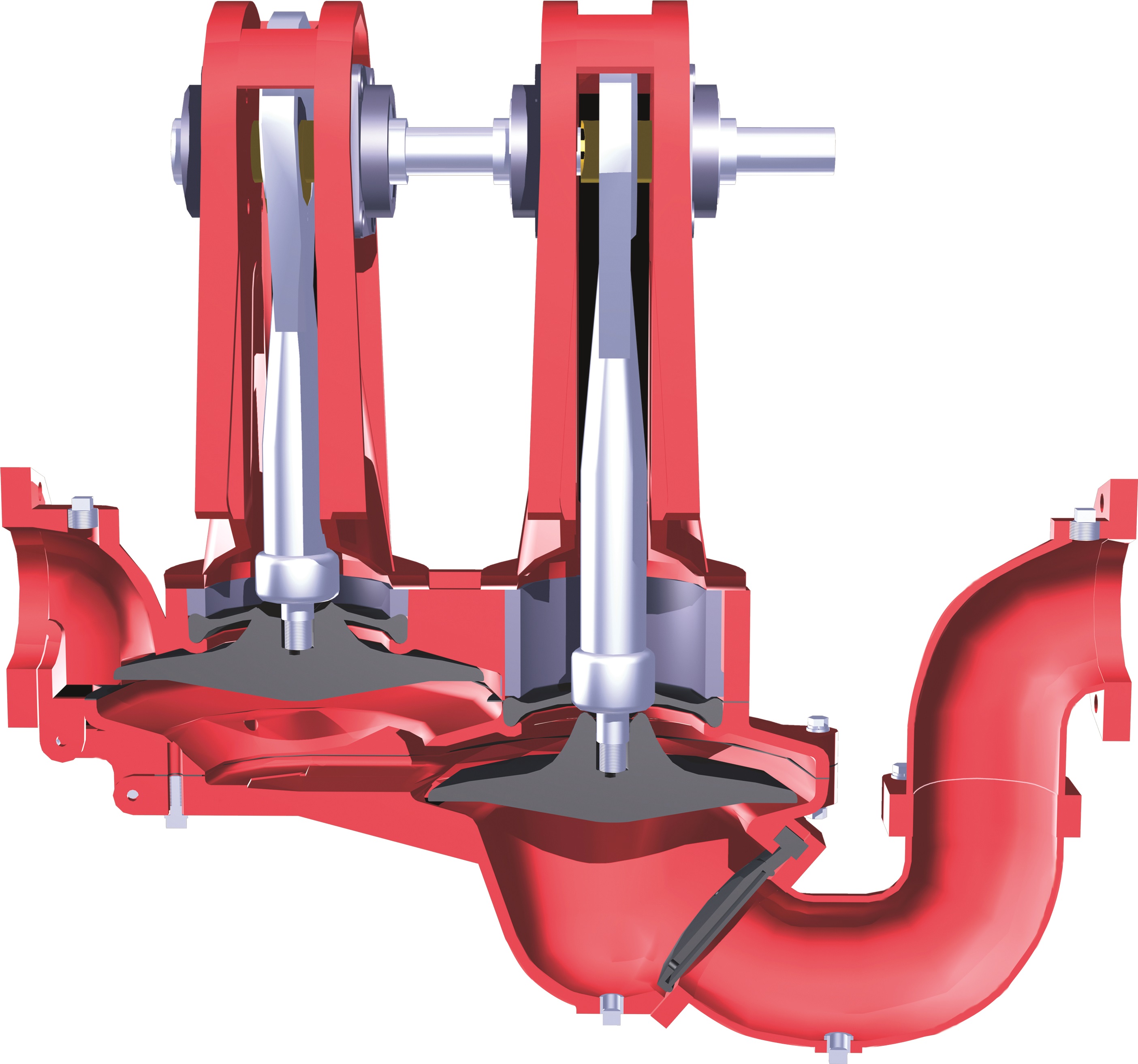

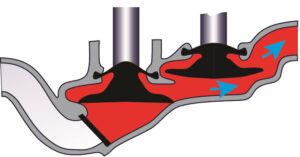

Double disc pumps are a type of reciprocating pump that is based on a non-captive free disc design where two discs are staged in the pump housing. These discs work in unison to perform the duties of both pumping element and valve element. The hydraulic interaction between the discs creates vacuum and pressure simultaneously to move fluid from suction to discharge. Very low friction takes place in the pump chamber, which leads to a longer operating life.

Double disc pumps are a type of reciprocating pump that is based on a non-captive free disc design where two discs are staged in the pump housing. These discs work in unison to perform the duties of both pumping element and valve element. The hydraulic interaction between the discs creates vacuum and pressure simultaneously to move fluid from suction to discharge. Very low friction takes place in the pump chamber, which leads to a longer operating life.

The unique design of the double disc pump makes it ideal for dewatering feed applications because of the relatively smooth flow that is generated from the pump action.

The double disc pump can achieve an operating life of 10,000 to 15,000 hours between rebuilds. This is two to three times the normal operating life of close tolerance rotary pumps. Spare parts cost approximately 10% of the initial capital purchase price. The pump is also gland-less and seal-less, with no oil lubrication or re-greasing requirements. There is no routine maintenance, and the pump can even run dry.

Choosing the Right Pump

All pumps have certain applications for which they are well suited. Knowing your system requirements and operating parameters helps you to determine which pump is right for your situation. Although pumps may technically be able to manage a task, that does not necessarily mean it is the correct pump for the job. Hopefully, this comparison will help in deciding when weighing your options.