Choosing a pump for fluid handling is both an investment and important choice. Durability, reliability and performance are the top three things that need to be considered when making that choice. No one in the municipal, industrial, chemical or food industries wants their pump to fail during operation. Pump failure not only means downtime for the facility, but it also means loss in revenue.

Oftentimes, facilities find themselves choosing between different styles of reciprocating positive displacement pumps, such as a double disc pump or a diaphragm pump. Let’s review what the differences are and help you decide which is best for your specific application.

Double Disc Pump Technology

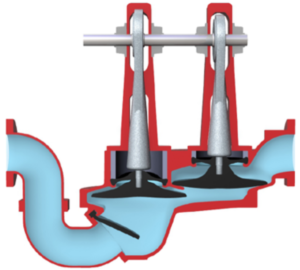

PVP double disc pumps are a unique type of positive displacement pump. This pump technology is based on a non-captive, free disc design where two discs are staged in the pump’s housing. These discs work together as both the pumping element and valving element. The hydraulic interaction between the discs creates vacuum and pressure at the same time to move fluid from suction to discharge.

These discs do not suffer from the flex fatigue pattern associated with captive diaphragm pump designs since they are not captive in the pump’s housing. They feature an integral elastomer design with a rigid core and do not have any external metal components.

The sealing device in the double disc pump is molded to flex only when it is in the downward stroke. This extends the seal’s operating life, allowing it to run for millions of cycles before replacement is required. .

How the Double Disc Pump Works

Double disc pumps are unique in that they have a short stroke length that is created by eccentric cams pinned to the drive shaft. The short stroke length produces small pulses and a relatively smooth flow. The pump is designed to provide positive valving on every stroke. This is possible because the discs are mechanically placed on the seat.

Double disc pumps are unique in that they have a short stroke length that is created by eccentric cams pinned to the drive shaft. The short stroke length produces small pulses and a relatively smooth flow. The pump is designed to provide positive valving on every stroke. This is possible because the discs are mechanically placed on the seat.

A double disc pump includes a clack valve which acts as a priming and re-priming aid. This valve is only activated if there is a suction lift condition or when the suction line is under a vacuum condition. If the pump is working during a flooded suction application, this valve does not get back to the seating surface and does not valve. The double disc pump will operate without the clack valve on flooded suction applications.

The pump’s unique design by mechanically placing the valving element on the seat allows larger solids, rags and debris to pass through the pump that would normally cause problems like clogging and failure in other pump designs. Depending on the pump model size, double disc pumps can handle solids up to 2 inches in diameter.

Diaphragm Pump Technology

Diaphragm pump technology is comprised of one ‘captive’ diaphragm that is attached between the pump’s housing and its retaining mechanism. A diaphragm pump is a simplex unit featuring one diaphragm and two ball check valves.

For applications that require increased flow rates, additional pumps can be added to the original design along with common motors to drive the pumps. For example, if a user would like a duplex diaphragm pump, another simplex pump is added in parallel to the original design and is driven by a common motor. A triplex pump adds a third pump and motor and so on.

One of the main weakness of diaphragm pump technology can be pinpointed to the flex fatigue of the diaphragm. The diaphragm flexes on both the upward and downward stroke, leading to twice the flexure rate. This overworking of the diaphragm leads to a shorter operating life.

How a Diaphragm Pump Works

Diaphragm pumps have a long-stroke cam arrangement. A connecting rod is mechanically attached to the center of the diaphragm. This rod raises and lowers the diaphragm on every revolution. Internal check valves, like a ball or flapper, are required for these types of pumps to function. Without them, the pump cannot operate. The pump’s long stroke length also produces large pulses and large pressure spikes in flow, making this pump less efficient than other designs.

Although good for some applications, diaphragm pumps generally do not do well in applications where larger pieces of debris, rags or solids need to be pumped out. This is due to likelihood of the ball check valves becoming clogged.

Check valves rely on gravity to get back to the seating surface. When something like large solids, rags or debris get caught between the ball valve and the seat, the pump stops pumping. And although these units have a quick release cap to access the ball valve that is clogged (because it is a frequent occurrence), no one wants to have to remove debris to make it operational again on a regular basis. It not only wastes time and money, it also wastes manpower.

Main Difference Between the Types of Pumps

The most significant difference between double disc pumps and diaphragm pumps is the flex fatigue. Diaphragm pumps experience flex fatigue because of the way they are designed.

Once the pump fails, a rebuild is needed. Diaphragm pump technology only has a lifespan of approximately hundreds of hours because of the flexing action of the diaphragm. Compare this to a double disc pump that has a lifespan of thousands of hours because the discs are non-captive and do not experience flex fatigue failure. Double disc pumps offer excellent reliability and far less long-term operation costs because they do not experience flex fatigue that in turn requires more maintenance.

When to Use Each Type of Pump

Choosing a pump for appropriate fluid handling in your application means judging many factors. Municipal, industrial and commercial applications that process sludge, slurry, scum and other wastewater with submerged solids need to consider how much downtime they can manage due to pump failure before it becomes a hindrance to facility performance and imperative to operational costs.

Certain pump designs are better suited to applications requiring efficiency and lower cost of ownership. Both reciprocating pump designs work in similar ways, but only true double disc pumps offer less clogging, less wear and less maintenance to reduce downtime and costs.